History Of Blackjack Knives

- History Of Blackjack Knives Youtube

- History Of Blackjack Knives Usa

- History Of Blackjack Knives 2020

- History Of Blackjack Knives Pictures

- History Of Blackjack Knives Video

Blackjack Knives began as a company importing and marketing knives for the South African-based knife producer and salesman, Chris Reeve. Chris Reeve Knives began trading in 1984, and Reeve made and sold various knives, including early models of the one-piece design popular in South African. Here is some information on the history of this knife from the man who designed the knife, former Blackjack Knives CEO Mike Stewart (this guy is a living legend in the knife world and pretty much a human encyclopedia on all things Knife) who has worked with, Pacific, Blackjack, Marbles and is now with Bark River.

Ek Commando Knife Co. or Ek Knives is an American combat knife brand produced by several different companies since the original founded by John Ek in 1941. In May 2014 the Ek brand was purchased by Ka-Bar which began selling its versions of Ek knife designs in 2015. Although not officially issued gear, Ek Knives have seen use by US forces in six major conflicts: World War II, the Korean War, the Vietnam War, the Gulf War, Afghanistan,[which?] and the Iraq War. Ek Knives manufactures Bowie-style blades, daggers, and a Fairbairn-Sykes MkII. President Franklin Delano Roosevelt, Clark Gable, and General George S. Patton have been identified as Ek knife owners.

World War II[edit]

A knifemaker since 1939, in January 1941, John Ek started producing knives in quantity in Hamden, Connecticut. By 1943 he was making six different styles of knives. By August 1944, demand for his knives had grown to the point where he had three shifts working around the clock seven days a week, to produce 10 different models.[1]

All of the knives made during WWII by Ek were numbered to help the owners keep track of them if they were lost, and because he guaranteed each knife for the lifetime of the original owner.[2] By keeping the original owner's name on record, he could follow up his lifetime guarantee system. Ek had very strong feelings about restricting his knives to active-duty US servicemen.[1]

It is reported that President Franklin D. Roosevelt kept a John Ek Commando Knife on his desk in the White House until the time of his death.[3] General George S. Patton, Jr. owned a John Ek Commando Knife (as did several of his subordinates); Ek eventually named his Model No. 6 the 'Patton Knife'.[3][4] Captain Clark Gable, while not necessarily expecting to see combat, purchased a number of Ek Knives while he served.[3]

Post WWII[edit]

In 1949 John Ek moved to Miami, Florida where he continued production of his knives. From here he provided knives to American forces during the Korean and Vietnam wars. Miami-produced knives were marked 'John Ek Knives, Miami, Fla.', whereas earlier knives bore the 'Hamden, Conn.' identification.[1]

John Ek died on October 21, 1976, but the business was continued by his son, Gary W. Ek who had worked for his father as a knifemaker since 1971 prior to John Ek's death. Due to the growing crime rate in Miami, the Ek family decided to relocate the operation to St. Augustine until 1982, when they moved it to Richmond, Virginia.[1]

In 1982 Ek Knife President Robert Buerlein took the reins and convinced John's Son and his Mother to move the company to Richmond, VA, with the new company slogan of 'Constant Improvement'. New knives have been introduced, developed by Gary Ek including the Raider/MCMAP Knife, authorized by the U.S. Marine Raider Association.[5] Handles were made of finely grooved black Micarta and hand-checkered walnut handles were offered as an upgrade. Machined brass X-nut screws to fasten the handle became standard instead of the original poured lead rivets. Blades were ground out of stainless steel and were mirror polished. Ek knives produced lower cost models with a handle made entirely of green or black (and occasionally 'desert camo') wrapped parachute cord and a heavy nylon-webbing sheath in a matching color. A number of variants, such as Ek bowie knives, hunting knives, throwing knives, boot knives and reproductions of other WW II patterns such as the Australian bowie and a copy of the Murphy-pattern combat knife were produced.[2]Since 1992, Chilean Marines Corps Commandos use the EK Knife as combat knife. Also, EK DAgger is part of the Marine Commandos Badge and ChMCSOC.

Blackjack Knives[edit]

In 1993 Blackjack Knives bought Ek, and moved production to Blackjack's plant in Effingham, Illinois.[6] Leather scabbards were discontinued to cut costs and the nylon-webbing sheath was instead substituted on all models. As Blackjack endured internal problems, they began producing small lots of different knives marked with the Ek brand in an attempt to catch the knife-buying public's attention.[7] Blackjack went bankrupt in 1997 and sold the remaining stocks of knives to Century International Arms. Some Ek knives made by Blackjack had a label stitched on the back of the nylon sheath reading 'Handmade in U.S.A.' over 'Ek Commando Knife Co' over 'Richmond, Virginia.'

History Of Blackjack Knives Youtube

KA-BAR Knives and current production[edit]

In 2014 KA-BAR Knives announced that they would acquire Ek Knife brand and reintroduce Ek-branded knives to the market. Production on the new knives began in 2015, and they remain in production.

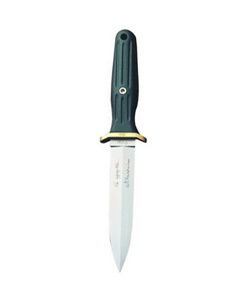

These current production knives are branded with both KA-BAR and Ek logos and are generally recognizable as Ek-style knives while sharing few design details with previous generations of the knives. Current production knives are constructed of 1095 steel, and feature black parkerized blades in a variety of styles, including the Model 4 spear point double edged knife and Model 5 clip point Bowie. All models feature glass filled nylon handles that mirror the shape of previous generations. Handles are attached with traditional x-head fasteners. A composite sheath is provided.

Construction[edit]

World War 2 in the United States was a time of steel shortages as it was a scarce strategic material. The U.S. Government War Production Board tested and approved the designs of John Ek's knives and authorized continued availability of the nickel-chrome-moly steel which he used. Subsequently, he was admitted to the Army Ordnance Association.[4]

Ek found the nickel-chrome-moly steel to be strong, yet stain and rust resistant. In later years Ek would use Swedish Sandvik stainless steel, upon request. In April or May 1939 John Ek designed the first John Ek Commando Knife which he named the Model No. 1 and that was the only model that he planned to make. The Model No. 1 had a single-edged blade of spearpoint design, with a sharpened false edge extending approximately three inches along the back edge of the blade.[4]

History Of Blackjack Knives Usa

Ek later developed a double-edged version of this named the Model No. 2. He added crossguards to these versions, designating them Models No. 6 and No. 7, respectively (today these are referred to as the No. 3 and No. 4).[2][4]

Several aspects of Ek's design made the knives distinct and rugged. The knife was made with a full-width, full-length tang (the extension of the blade which runs through the grips) construction. Not only did the tang run the entire length of the grips, but the tang was the full width of the grips. Most knives of the day (even ones made today) had narrow 'rat-tail' tangs, many running only one-third the length of the grip. Ek believed his full tang design made the knife inherently stronger.[4]

Ek's knives featured an extended butt, a direct extension of the blade and the blade tang itself protruding beyond the end of the handle slabs anywhere from nearly 1/2 ' to 1'. This allowed the butt end of the knife to be used as a pry bar for opening ammunition crates or, according to Ek's 1944 manual, Your Silent Partner, for 'an upstroke to lay your opponent out.' Another use of this extension was to protect both the hand and the wooden grips when the butt was used as a hammer. The extended butt of the Ek Commando Knife may have inspired the design of the 'skullcrusher' pommel on the First Special Service Force V-42 Stiletto, which appeared in 1943.[5]

Ek preferred wood grips to leather, as the leather was prone to rot under tropical conditions. He found the rock maple grips he chose to be more comfortable and to provide a better grip, especially when the hand was wet with perspiration, than the brass/alloy grips of the British Fairbairn-Sykes Fighting Knife. The wood grips allowed the owner to custom fit the grip, by sanding, to the exact contour of his hand. For a number of years, Ek included a piece of sandpaper with each knife for this purpose.[2]

Ek preferred his knives without crossguards for ease of concealment and for quick withdrawal as there was no crossguard to snag on clothing or a soldier's equipment. The grips on Ek's knives had eight scalloped groves:four on each of two grips. This gave the user such a good grip that John Ek found that a crossguard was not necessary to prevent the hand from sliding onto the blade. When questioned about this by the War Production Board, Ek greased his hand and plunged one of his knives into the wooden floor with such force that no one was able to pull it out.[4]

The 'Poured-Lead' Rivets which were used to affix the two wooden grips to the blade tang were unique to Ek Knives. Most knives at the time used standard cutlery rivets or pins, or they were simply driven onto the rat-tail tang. The Poured-Lead Rivets had the advantage that, if the grips ever became loose, they could be tightened in the field without any tools. All the owner needed to do was take a heavy object, such as a rock, and pound the lead rivets to tighten them. Another advantage of the Poured-Lead Rivets was the extra weight which made the knife balance far better than most, as it added weight to the hilt. This caused it to fall into the hand, rather than fall out of the hand.[4]

EK Commando Knife used by Chilean Marines Commandos (Chilean Marine Corps Special Operations Command)

References[edit]

- ^ abcdLewis, Jack; Roger Combs (1992). Gun Digest Book of Knives. Gun Digest. ISBN978-0-87349-129-7.

- ^ abcdPrice, C. Houston; Mark D. Zalesky (2008). Official Price Guide to Collector Knives. Random House. pp. 106–108. ISBN978-0-375-72280-6.

- ^ abcAhern, Jerry (2010-04-01). 'Ek Bowie'. Gun World. 60 (4): 6–8.

- ^ abcdefgCampbell, Robert (2006). 'Ek Commando Knives: the Legend Lives On'. Tactical Knives: 66–68.

- ^ abBuerlein, Robert. (2002). Allied Military Fighting Knives: And The Men Who Made Them Famous. (Chapter 5). Paladin Press. ISBN1-58160-290-1

- ^Campbell, Bob (April 2006). 'The Ek Commando Knife'. 32 (4). Knife World Publications: 106–108.Cite journal requires

journal=(help) - ^Walker, Greg (1993). Battle Blades: A Professional's Guide to Combat/Fighting Knives. Boulder, Colo.: Paladin Press. p. 35. ISBN0-87364-732-7.

History Of Blackjack Knives 2020

External links[edit]

- http://www.kabar.com/video/detail/132120621 Rebirh of Ek Knives KA-BAR company video

History Of Blackjack Knives Pictures

History Of Blackjack Knives Video

by Anne Reeves

When the sole proprietorship “Chris Reeve Knives” began trading in January 1984, it was from the single garage attached to the house in which Chris was living. He worked by himself, making and selling various designs of knives, including the early models of the one-piece design, in the local South African market. Early in 1985, he received his first inquiry from the United States. Shortly thereafter, a shipment of one-piece knives was exported to Moteng International in Los Angeles.

Because of the promise of regular and substantial orders from Moteng, he moved into a home with a larger garage in July 1985 and hired a young assistant. All the time, Chris was working at improving production methods and increasing production capacity. In November of 1985, he received an inquiry from American Manor House in Baltimore, MD who, during the next 12 months, made significant purchases.

The business had the potential for growth and because the South African market was limited, the growth had to come from export. Chris decided the best way to approach the export market actively was to exhibit at a Custom Knife Show in the United States. He applied for and received, a table at the New York Custom Knife Show in November 1986. This show presented an opportunity for which Chris had been waiting a long time - to see how his work compared with the best in the world. It was very gratifying to see that his work was well on par; he made fairly good sales and met a vast number of new contacts.

Among the people he met was Mike Stewart who, together with a young South African, Steven Lewis, formed a company called Blackjack Knives early in 1987. Blackjack Knives took premises in Los Angeles and they planned to import and sell the Chris Reeve range of one-piece knives as well as develop their own range. Between April and November, Blackjack purchased a large number of one-piece knives and they did an excellent job of promoting the product. However, the company was poorly managed and almost went bankrupt at the end of 1987.

During a 1987 visit to the USA, Chris exhibited at the California Custom Knife Show in October and the New York Custom Knife Show in November. He was well received by the buying public and knifemakers alike. He applied for membership of the (USA) Knifemakers Guild, was granted probationary status in July 1988 and became a voting member in 1990.

The period between January 1988 and February 1989 was one of tremendous activity. Even though there had been an initial setback because of the collapse of Blackjack Knives, three USA companies began importing directly. Markets were opened in England, France, Italy, Australia, and Hong Kong. A staff of five - Chris, Anne (his wife who had been working full-time in the company since January 1987) and three full-time employees - produced approximately 1,600 units during this period.

While there were several advantages in exporting from South Africa (the exchange rate and the excellent Export Incentive Program offered by the South African Government) these were outweighed by the disadvantages. The continuing political strife resulted in a spiraling cost of living (and production), the worldwide threat of sanctions and trade embargoes and the general anti-South African feeling, made regular export very tenuous for a small business.

It seemed that the most sensible thing to do would be to move to the United States. Lengthy and careful consideration was given to the move and the choice of location. Boise, Idaho was chosen for several reasons, the most important of which was that the city is large enough to provide the services required for the business yet small enough to allow newcomers to find their feet. The beautiful countryside of Idaho offers the space for recreation activities like hiking, camping, and appreciation of the wilderness.

Chris and Anne arrived in Boise in early March 1989 and within six weeks had occupied workshop space and were producing finished knives. The first year or two in the USA was difficult. There was so much to learn - how to, where to and who to - were questions asked daily. Chris and Anne attended 12 knife shows all over the USA between July 1989 and April 1990 - an exhausting but beneficial way to make the presence of Chris Reeve Knives known. The companies previously importing the knives had frequently misrepresented the product and now many misconceptions were cleared.

But the overall pattern was growth. By 1991, Chris was able to cut down the number of shows to six large and/or prestigious shows a year; he employed an assistant; the range of one-piece knives grew to 21 different models; Chris was making selected high-dollar, purely custom knives as time permitted. Advertising in dedicated knife magazines produced a constant source of retail sales and a slow but steady building of a dealer base. Exports, particularly during 1992, were exceptional.

Every cent earned was reinvested in machinery. Continual attention was placed on refining the product, the methods of making the product and ensuring that the product was what the customer wanted. Because quality control and customer service are such important facets of the company, additional staff was employed.

In 1991, Chris introduced his folding knife, the Sebenza - Chris Reeve Small Sebena & Chris Reeve Large Sebenza. The success of this design has been phenomenal. As a result of an article in the Fall 1990 issue of Fighting Knives, 75 orders were received from retail customers - none of whom had ever actually held the knife. An initial 86 purely hand-made large Sebenzas were made and supplied during 1991. During this time, Chris was researching methods of making the knife more efficiently and in September 1991, purchased a $40,000 computer-controlled machining center. This was a major step forward and a steep learning curve lay ahead but it was now possible to increase the quality and the consistency of the components for the folder. A smaller size Sebenza was introduced in October 1992. Continual development goes into variations on the integral lock theme, including embellishment of the handle, inlays, and different blade materials.

In July 1993, Chris Reeve Knives, sole proprietorship, became Reeve Incorporated, trading as Chris Reeve Knives. The company brochure produced in April 1994 showed a refined line of one-piece knives. The reduced range better represented current market trends and allowed Chris Reeve Knives to continue to produce quality, affordable cutlery.

The period 1994 through mid-1996 was a time of consolidation, and then followed a time of great activity. A front cover article in Tactical Knives magazine in July 1996 of a new profile Sebenza virtually doubled backorders for the folding knives and greatly increased interest in the fixed blade knives. In November 1996, we moved into a new 4,000 sq. ft. facility and purchased two new machines to assist in the production of Sebenzas. In July 1997, the Umfaan, a smaller version of the Sebenza, was introduced and sales have been beyond expectation.

January 2000 saw the launch of the Classic Sebenza. In the time since Chris had introduced the new profile Sebenza in July 1996, many customers had requested the original profile knife, which was no longer available. As an acknowledgment of the turn of the millennium, we introduced the Classic MM (2000) in both large and small sizes. There were some minor differences from the original knife but the more angular profile was the same.

At the Blade Show and International Cutlery Fair in Atlanta, GA during June 2000, Chris Reeve Knives exhibited for the first time as a fully-fledged manufacturer. This allowed the company to enter a product in some of the different categories voted upon by other exhibiting manufacturers. The resulting industry awards are highly prized and so it was with great pride that we received the “Manufacturing Quality Award” for 2000. Building on this prestigious achievement, Chris Reeve Knives proudly received the award for the second time in 2001.

It had been several years since any brand new knife concept came from Chris Reeve Knives and so by the Shot Show 2001, the time was right for the introduction of the Chris Reeve Mnandi. This elegant, discreet pocket knife is perfect for a business person because it is very functional but looks entirely non-threatening. Orders before the actual availability of the Mnandi were exceptional and demand continues to be very high.

June 2002 saw a new phase in the history of Chris Reeve Knives. Working in collaboration with custom knifemaker Bill Harsey and Tactical & Survival Specialties, Inc., a company that provides logistical support for special operations teams, we submitted a fixed blade knife to U.S. Army Special Operations Command with the anticipation that it might be selected as the knife to be presented to all graduating Special Forces soldiers. The submission was successful and we are very privileged to make “The Yarborough”, a knife that is presented to every graduate of Special Forces Q Course. The Yarborough is also available to current and retired SF, and a civilian version, known as Chris Reeve Green Beret is available to the public at large. Response to this knife has been exceptional!

At the Blade Show in Atlanta, GA in June 2003, the Yarborough/Green Beret knife was judged “Knife Collaboration of the Year”. Chris Reeve Knives was also the proud recipient of the Manufacturing Quality Award – the only three-time winner of this award.

While we anticipate that world events will impact both our business and the knife industry in general, we look confidently to the future – where Chris Reeve Knives will show that exceptional design and quality craftsmanship are always desired.